PPGI Roofing Sheet

PPGI Roofing Sheet

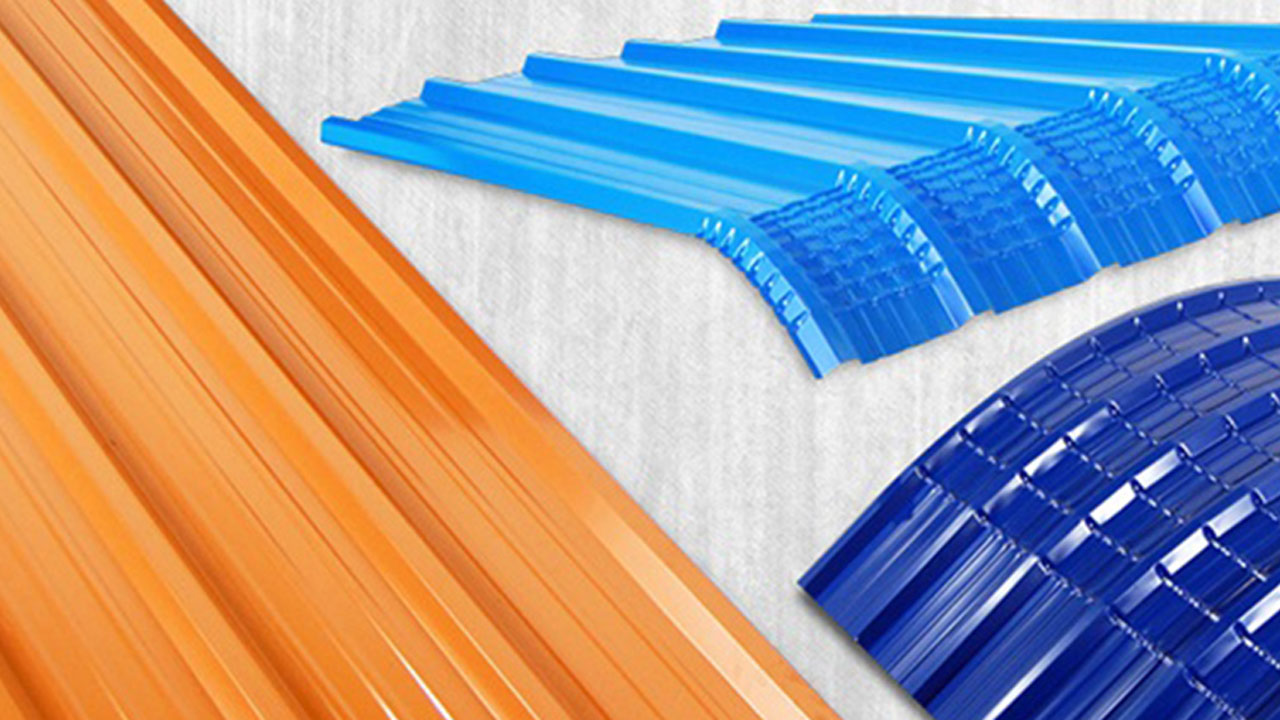

PPGI (Pre-Painted Galvanized Iron) steel sheets represent a coated steel sheet with enhanced aesthetic appeal and corrosion resistance. Produced by applying a layer of paint or coating onto a galvanized steel substrate, PPGI sheets offer versatility, ease of installation, and a wide range of colors and finishes for various applications.

PPGI roofing sheet offers beauty and durability to suit all your agricultural, residential and commercial needs. A factory to provide a wide range of PPGI roofing sheets with different designs and sizes. The available thickness is from 0.2 to 0.8 mm, and the width is from 600 to 1,250mm.

Types of PPGI roofing Sheet

- Polyester Coated PPGI Sheets

- SMP Coated PPGI Sheets

- HDC PPGI Sheets

- PVDF Coated PPGI Sheets

- Plain/Flat PPGI Roofing Sheets

- Corrugated PPGI Roofing Sheets

- Tile Profile PPGI Sheets

- Wave PPGI Roofing Sheets

- Thin Gauge PPGI Sheets

- Thick Gauge PPGI Sheets

- Residential PPGI Roofing Sheets

- Industrial PPGI Roofing Sheets

Specification

| Item | PPGI Roofing Sheet |

| Thickness | 0.2 mm-0.8 mm |

| Overall Width | 750 mm-1,500 mm |

| Effective Width | 600 mm-1,250 mm (Common width: 914mm, 1,000mm,1200mm, 1220mm) |

| MOQ | 10 Tons or 500 pieces |

| Design | Wave, Trapezoid, Tile, etc. |

| Colors | As per RAL Color (custom patterns are available) |

| Coatings | PE, SMP, HDP, PVDF |

| Certificates | ISO 9001, SGS, CE, BV |

| Features | Durable Coating, Corrosion Resistant, Waterproof |

| Package | Standard Export Package |

Product Features

- Durability: The pre-painted coating also adds an extra layer of protection against harsh environmental elements like UV rays, salt, and acidic rain.

- Durability: High-quality fencing wire is designed to withstand harsh weather conditions (rain, wind, UV rays) and physical wear. Galvanized and PVC-coated wires are particularly resistant to corrosion and rust, which prolongs their lifespan.

- Wide Range of Colors PPGI sheets come in a variety of vibrant colors and finishes, including matte, glossy, and textured. This allows for better aesthetic integration into different architectural designs.

- Weather Resistance Coatings like PVDF (Polyvinylidene Fluoride) and SMP (Silicone Modified Polyester) offer excellent resistance to UV rays, preventing the sheet from fading over time.

Manufacturing Process

- Steel Coil Preparation: The process starts with cold-rolled steel coils (also called base metal), which are cleaned and pre-treated to remove any impurities such as oil, dirt, and rust.

- Hot-Dip Galvanization: In this step, the steel coils are passed through a molten zinc bath at a temperature of around 450°C. The zinc coating bonds with the steel through a process called diffusion.

- Chromium Passivation: After the galvanizing process, the steel coil surface is treated with a chromium-based solution or other passivating agents. This layer enhances the corrosion resistance and prevents the zinc coating from deteriorating over time.